2023-01-11

2023-01-11

loading...

loading...

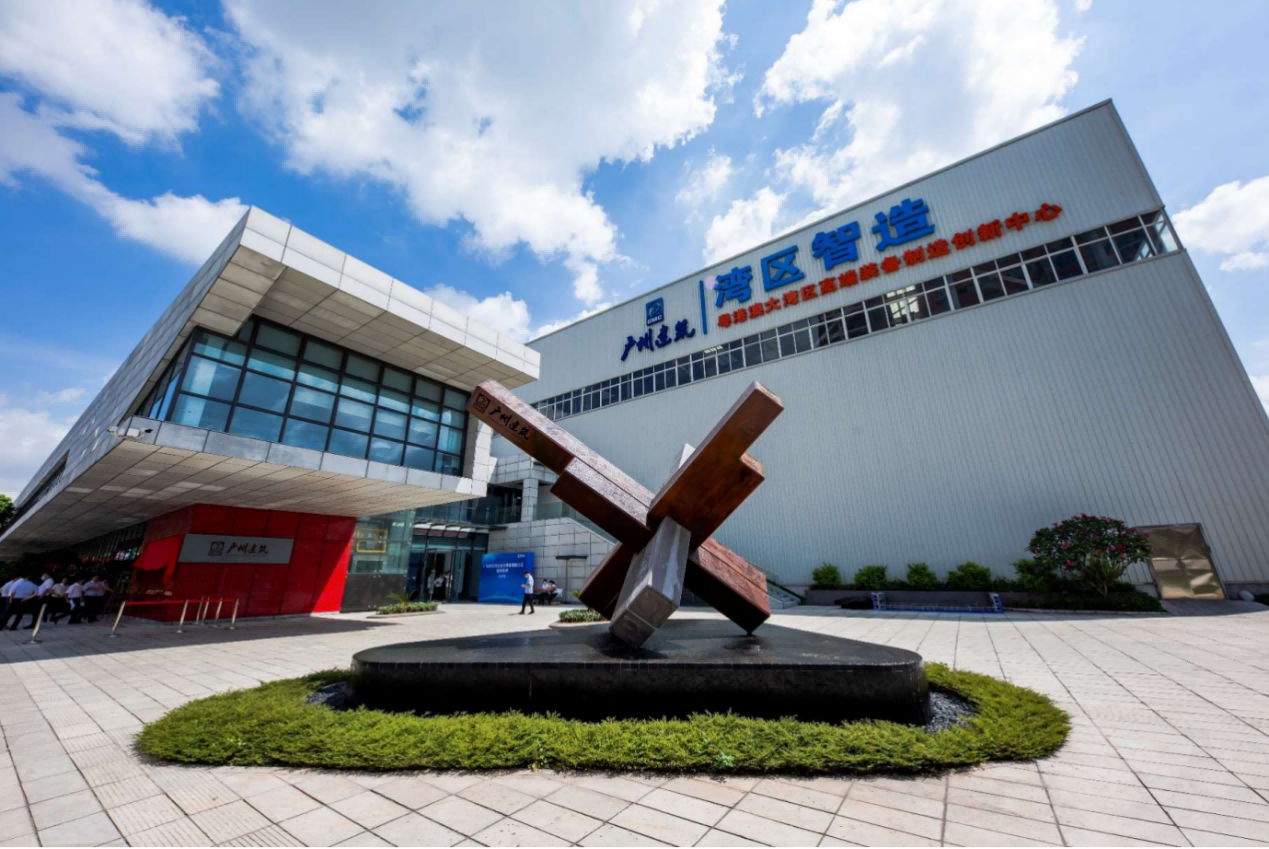

The first list of the National Quality Engineering Awards 2022–2023 has been unveiled recently. The municipal supporting project around the new resettlement community by Gualv Lake in Zengcheng District (Licheng Area) under a project to improve the living environment of Licheng Sub-district built by Guangzhou Municipal Engineering Machinery Construction Co., Ltd., GMC, won the highest honor for the quality of engineering construction in China.

The project is launched to introduce urban elements into villages, marking Zengcheng District’s efforts to facilitate integrated urban and rural development in Guangzhou.

The project has further improved the urban system, effectively addressing the living needs of residents in the new resettlement community by Gualv Lake (Licheng Area), improving the living and investment environment in Zengcheng District, and greatly supporting Guangzhou to implement the “eastward” strategy.

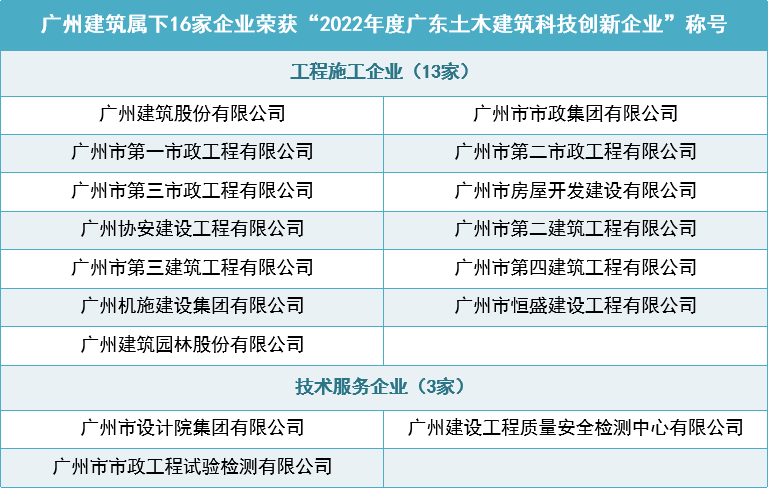

With a cost of RMB 830 million, the project was commenced on January 10, 2017 and completed on May 20, 2020. It constructed 11 municipal roads, one flyover, water supply and drainage pipeline works, water supply and drainage structure works, electrical works, traffic works, lighting works, greening works, and garden ancillary works. The project has won the third-class achievement in design level evaluation of the China Association of Construction Enterprise Management, the Guangdong Municipal Gold Award, the Guangdong Construction Engineering Quality Award, and the honor of Guangdong Municipal Excellent Model Project. By dint of domestic leading scientific innovation in the same period, it has won five provincial and ministerial science and technology awards.

Green Construction with Highlights

Practicing the concept of green development, the project has adopted the concave design for green belts that facilitates the collection and infiltration of runoff rainwater, enabling the integration of sponge-like facilities and garden landscapes. Road arrangement has been optimized in consideration of bypassing village ancestral halls and Fengshui ponds to protect ancient ancestral hall buildings. The logo is designed with local culture represented by regional elements such as the Gualv Lake and Gualv litchi, and the project is integrated with road facilities such as guardrails, decorative manhole covers, and bus stops and aims to create the characteristic culture of Gualv litchi.

The project has applied prefabricated retaining walls to build multi-stage ecological slope protection. The retaining wall components were prefabricated in the factory, and the cast-in-place technology was used to connect the joints between the components, which greatly shortens the construction period and improves the quality.

Digital Support to Coordinate All Parties

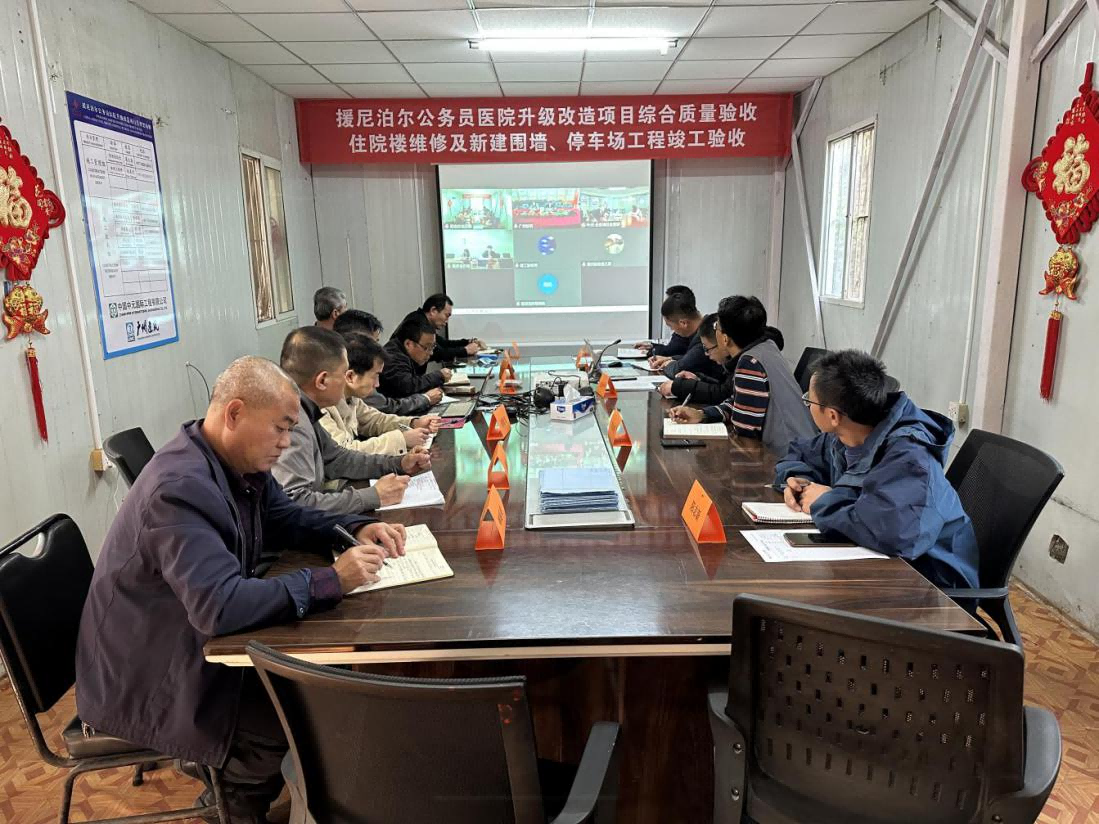

During the construction process, all parties involved adopted the smart site big data management system to realize fine management of construction projects. The project shifted the focus of the application of BIM technology to the data integration applications such as cost and schedule in the construction phase.

At the same time, the project adjusted the construction plan timely to overcome difficulties such as high requirements for green construction, a heavy workload for pipeline protection and demolition, coordination between traffic and construction arrangements, and high safety and civilized construction standards. The construction was promoted with high efficiency and high quality based on maintaining the original road capacity.

Innovative Application with Outstanding Results

The non-motorized vehicle lane has a completely permeable composite pavement structure made of “fine-grain, colorful strong cement concrete, C25 permeable concrete with primary color, cement-stabilized macadam, and dense graded macadam”, which enables rainwater to infiltrate directly into the ground through the permeable pavement to relieve drainage pressure.

Road-bridge transition sections are set up between the roadbed and the abutment, greatly reducing bumps at the bridgehead of the flyover. Crushing machines were used to crush the old concrete pavement and other construction waste into particles with a maximum particle size of 31.5 millimeters to form concrete recycled aggregate, which was used as auxiliary road subgrade filling materials. This practice realized the recycling of waste materials.

Source: Feng Aihong (text) and Mo Zihao (picture) of Guangzhou Municipal Group Co., Ltd.

Edited and released by Li Zhaowen and Lu Chongyou, Party-Masses Work Department of the Group

Released by Zhang Xiaoying, Group Office